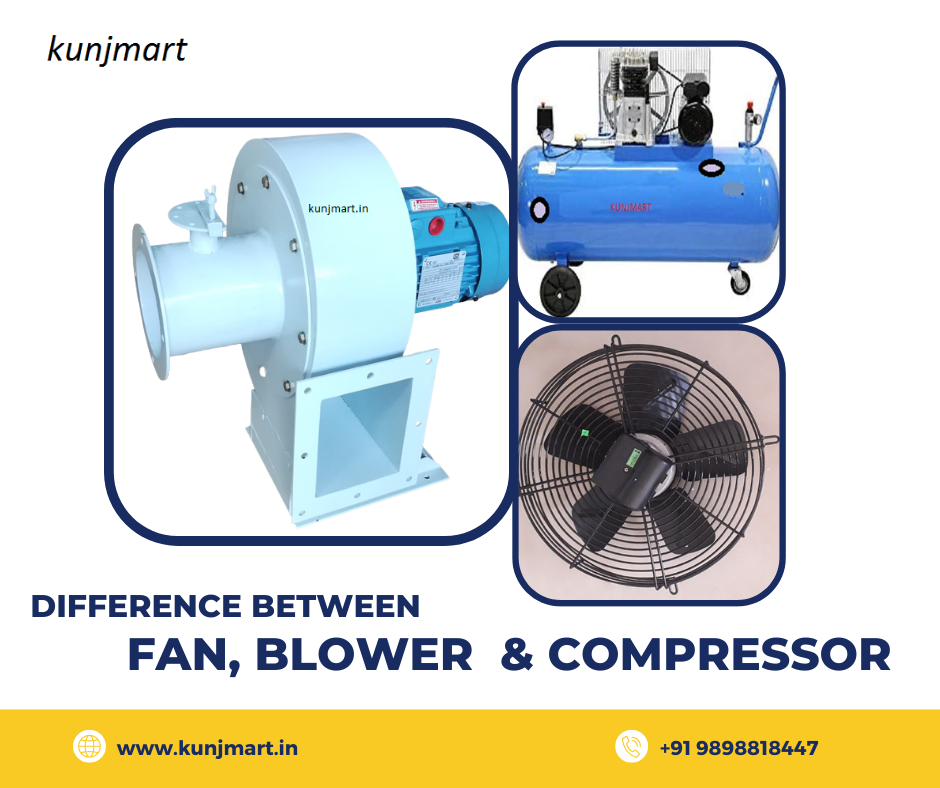

Equipment such as Centrifugal blowers, Extruder blowers, Blow molding machine blowers, Ventilation fans, Fan blowers, and Air compressors are important devices. However, many people, especially business owners, are not aware of the variations between them all. There are significant distinctions between fans, blowers, and compressors, even though there are some similarities. There is a high -tech difference between fans and blowers in connection to functioning, operating, and designing but fundamentally both fans and blowers are used for ventilating the electronics machines.

The variations between fans, blowers, and compressors are summarized here. You'll find out more about the commercial applications for them as well.

In general, fans are thought to have pressure ratios of up to 1.11. Here, pressure ratio is referred to as the ratio of the fan input pressure, also known as the suction pressure, to the fan discharge pressure. 1.11 and lower pressure ratios are extremely low. Think about the fan in your living area that keeps you cool during the summer. This fan's function is to cool your skin by forced convection by pushing air around your body at a moderate pace. This only requires a slight increase in pressure. Only local losses within the fan itself, such as limitations in the fan blading, resistive losses from other sections of the fan, like the fan enclosure, and downstream mixer losses, must be overcome by the fan. Since there is ambient pressure immediately upstream and immediately downstream of the fan, the pressure rise created by the fan swiftly compensates for these local losses. Fans are often machines that circulate higher volumes of an air with a negligibly increased pressure.

Sometimes, the words fan and blower are used interchangeably. Generally speaking, a blower has a pressure rise that is between 1.11 and 1.2 higher than a fan. Once more, the difference between the discharge pressure and the inlet pressure is the pressure rise. When the system resistivity is greater than that of a fan, air blowers are utilized. It is useful to think of a blower as a machine that must move an air through a system with a higher resistance than a fan's cage, such as ducting. A straightforward illustration is a forced-hot-air furnace that must circulate air inside a house. Another example is a blow dryer, which has to overcome somewhat larger system losses than a standard fan. A blower is typically thought of as a machine that pushes a lot of air against a moderate level of system resistance.

The device is typically referred to as a compressor for situations when the desired pressure rise is larger than 1.2 since more "compression" is performed. In actuality, a compressor's main function is not so much to move a lot of air as it is to raise the gas's pressure. The turbocharger in your car is one excellent example. A pressure ratio of 3.5 may be used by the turbocharger compressor to force (compress) air into the engine. For thermodynamic or structural reasons, the system in this kind of application prefers to function at a greater pressure level. Larger pressure rise is necessary in other applications because system losses are substantially larger. Comparing the volumetric flow rates to a cooling fan or blower, they are frequently seen as being quite low. There are exceptions to every rule, and compressors with very high flow rates are used in numerous industrial applications. Compressors, particularly centrifugal compressors, frequently have pressure ratios that are far higher than 1.2. In a single step, pressure ratios greater than 10 have been accomplished. A compressor may thus produce a substantially larger pressure rise throughout a broad flow rate range.

In conclusion, consider how fans, blowers, and compressors are chosen and characterized based on the application, particularly the process resistance, with the necessary pressure ratio varying for each of these three devices: The varying quality requirements for these three devices have led to variations in fan, blower, and compressor impeller designs, pressure rise proportion to flow rate, and other factors.